Overview of the 2.4 Ecotec Engine and Timing Chain System

The 2.4 Ecotec engine features a durable timing chain system designed for reliable performance in various GM vehicles. It ensures precise synchronization of engine components, including valves and pistons, while the timing chain guide bolts play a critical role in maintaining system stability and preventing common failures.

1.1 Importance of Timing Chain Components

The timing chain components are vital for maintaining the precise operation of the 2.4 Ecotec engine. They synchronize the rotation of the crankshaft and camshaft, ensuring that valves open and close in harmony with piston movements. This prevents collisions between pistons and valves, which could lead to catastrophic engine failure. The timing chain, guides, and tensioners work together to reduce wear and tear, while the bolts secure these components firmly in place. Over time, however, these bolts can shear due to stress, leading to chain misalignment and potential engine damage. Regular inspection and maintenance are crucial to prevent such issues and ensure reliable engine performance.

1.2 Role of Timing Chain Guide Bolts in Engine Performance

The timing chain guide bolts are essential for securing the timing chain guides in the 2.4 Ecotec engine, ensuring proper alignment and tension of the timing chain. These bolts prevent the guides from shifting under engine stress, which could lead to chain misalignment and premature wear; Their stability directly impacts engine performance, as any failure can disrupt the synchronization between the crankshaft and camshaft. Over time, the stock bolts may shear due to repeated stress, risking engine damage. Upgrading to high-strength bolts, such as ARP or ZZP, enhances durability and prevents potential failures, ensuring smooth and reliable engine operation under various driving conditions.

Understanding the 2.4 Ecotec Timing Chain Guide Bolts

The 2.4 Ecotec timing chain guide bolts are critical components made from high-quality materials, redesigned to prevent common failures and ensure reliable engine operation.

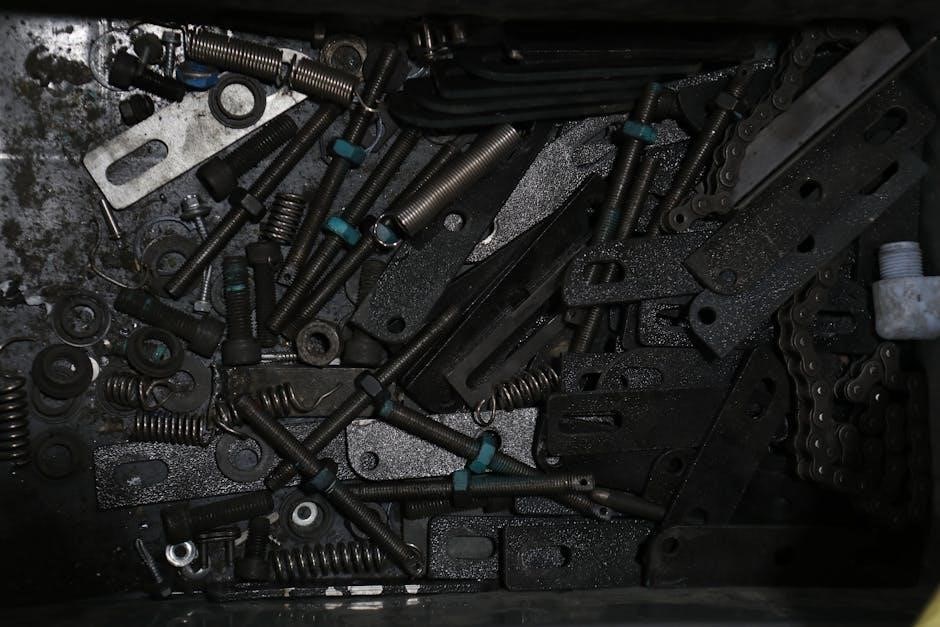

2.1 Design and Function of the Timing Chain Guide Bolts

The timing chain guide bolts in the 2.4 Ecotec engine are designed to secure the timing chain guides, ensuring proper alignment and tension of the timing chain. Made from high-strength materials, these bolts feature an Allen key head for easy installation and torque specification compliance. Their primary function is to prevent the timing chain from shifting or jumping teeth, which could lead to engine misfires or catastrophic damage. The bolts are engineered to withstand the stresses of engine operation, providing a reliable connection between the timing chain components and the engine block. Upgraded versions often use advanced alloys for added durability.

2.2 Common Issues with Stock Timing Chain Guide Bolts

Stock timing chain guide bolts in the 2.4 Ecotec engine often face issues related to durability and reliability. One common problem is the tendency of the bolts to shear over time due to the high stresses exerted by the timing chain. This shearing can lead to misalignment of the timing chain, causing engine misfires and potentially catastrophic damage. Additionally, the stock bolts are made from materials that may not withstand prolonged engine operation, making them prone to fatigue and failure. These issues highlight the need for upgraded solutions to ensure long-term engine performance and reliability.

Upgraded Timing Chain Guide Bolt Solutions

Upgraded solutions like ZZP, ARP, and GM Genuine Parts offer high-strength alloys and improved designs to prevent shearing and enhance durability, ensuring reliable engine performance.

3.1 ZZP Upgraded Timing Chain Guide Bolt

The ZZP upgraded timing chain guide bolt is designed to address the common issue of stock bolts shearing over time. Made from a higher-grade alloy than the stock bolts, it provides increased strength and durability. This bolt is specifically engineered for GM Ecotec engines, including the 2.4L, and is compatible with vehicles like the Chevrolet HHR, Malibu, and Pontiac G5. The ZZP bolt ensures improved reliability and prevents potential engine damage caused by timing chain guide failure. Its robust design makes it a popular choice for preventative maintenance and performance upgrades, offering peace of mind for drivers seeking long-term engine stability.

3.2 ARP High-Strength Timing Chain Guide Bolts

ARP high-strength timing chain guide bolts are a premium upgrade for the 2.4 Ecotec engine, offering exceptional durability and reliability. These bolts are crafted from high-grade materials and feature a grade 12.9 rating with an Allen key head. With a minimum strength of 174,000 psi, they significantly outperform stock bolts, reducing the risk of shearing and failure. Designed for compatibility with GM Ecotec engines, ARP bolts are ideal for drivers seeking enhanced performance and longevity. Their robust construction ensures precise alignment and stability of the timing chain system, making them a trusted choice for both preventative maintenance and high-performance applications.

3.3 GM Genuine Parts Timing Chain Guide Bolts

GM Genuine Parts timing chain guide bolts are designed and engineered to meet the stringent standards of General Motors, ensuring optimal performance and durability for the 2.4 Ecotec engine. These bolts are precision-crafted to fasten vehicle components securely, providing reliable operation of the timing chain system. Backed by GM’s reputation for quality, they are a direct replacement for stock bolts, offering consistent strength and resistance to wear. GM Genuine Parts bolts are a cost-effective solution for maintaining the integrity of the timing chain system, ensuring proper engine synchronization and preventing potential failures related to the timing chain guide bolts.

Installation Tips for Timing Chain Guide Bolts

Use a torque wrench to ensure proper tension, and apply threadlocker to prevent loosening. Clean the area thoroughly before installation to avoid contamination and ensure a secure fit.

- Follow the manufacturer’s torque specifications.

- Inspect the timing chain system for wear before installing new bolts.

4.1 Tools and Materials Required for Installation

To install timing chain guide bolts, essential tools include a torque wrench, Allen key, and socket set. Materials needed are high-strength threadlocker, new guide bolts, and RTV silicone for sealing. Additional items like a cleaning brush and lubricant may be required for preparation. Ensure all tools are compatible with the specific bolt type, such as Grade 12.9 or ARP bolts, to avoid damage. Proper tools and materials are critical for a secure and durable installation, preventing future issues like loosening or leaks.

4.2 Step-by-Step Installation Guide

Begin by loosening the old timing chain guide bolts using an Allen key or socket wrench. Remove the bolts and clean the threads thoroughly. Apply a high-strength threadlocker to the new bolts and insert them into the guide. Tighten in a star pattern to avoid misalignment. Torque to the manufacturer’s specifications, typically around 30-40 ft-lbs. Allow the threadlocker to cure for 30 minutes before starting the engine. Double-check all bolts for proper seating and torque. Ensure the timing chain is aligned correctly to maintain engine synchronization. Follow these steps carefully to prevent damage and ensure long-term reliability of the timing chain system.

Compatible Vehicles and Engines

The 2.4 Ecotec timing chain guide bolts are compatible with Saab 9-3 (2003-2012), Saab 9-5 (2010-2011), Opel 2.2, and select Chevy models with the 2.4L engine.

5.1 List of Vehicles Using the 2.4 Ecotec Engine

The 2.4 Ecotec engine is utilized in various General Motors vehicles, including the Saab 9-3 (2003-2012), Saab 9-5 (2010-2011), and Chevrolet Malibu (2004-2008). Additionally, it powers the Chevrolet HHR (2006-2011), Pontiac G5/Pursuit (2006-2010), and Saturn Vue (2002-2010). This engine is also found in Opel models, such as the Opel 2.2, further showcasing its widespread application across GM’s global lineup. These vehicles benefit from the engine’s balance of performance and efficiency, making it a versatile choice for both compact and mid-size cars.

5.2 Engine Codes and Specifications

The 2.4 Ecotec engine is identified by specific codes, including the LE5 and LE9, which denote its performance and application variations. Featuring a displacement of 2.4 liters, this inline-four cylinder engine produces horsepower ranging from 164 to 182, depending on the model year and configuration. With a torque output of approximately 160-170 lb-ft, it ensures smooth power delivery. The engine’s aluminum block and cylinder head design contribute to its lightweight and efficient operation. These specifications align with its use in various GM and Opel vehicles, making it a reliable and enduring powerplant across multiple model lines and generations.

Common Problems and Failure Symptoms

The 2.4 Ecotec engine often experiences timing chain guide bolt issues, including shearing or loosening, leading to chain misalignment. Symptoms include unusual rattling noises and reduced engine performance.

6.1 Signs of Timing Chain Guide Bolt Failure

The primary indicators of timing chain guide bolt failure in the 2.4 Ecotec engine include unusual rattling or clunking noises from the engine, particularly during acceleration or deceleration. Drivers may also notice a noticeable decrease in engine performance, such as rough idling or stumbling. In some cases, the check engine light may illuminate, signaling a misfire or other related issues. If left unchecked, these symptoms can escalate, leading to catastrophic engine damage. Early detection is critical to prevent costly repairs, as a failed bolt can cause the timing chain to jump teeth or break entirely, resulting in severe mechanical failure.

6.2 Consequences of Ignoring Timing Chain Issues

Neglecting timing chain issues in the 2.4 Ecotec engine can lead to severe and costly damage. A failed timing chain or guide bolt can cause the chain to jump teeth or break, resulting in improper valve timing and potential contact between valves and pistons. This can cause bent valves, damaged piston heads, or even cracked cylinder walls. Such failures often require extensive repairs, including head replacement or a complete engine rebuild. Ignoring early warning signs like rattling noises or decreased performance can escalate into catastrophic engine failure, leaving the vehicle inoperable and requiring thousands of dollars in repairs.