Shore Hardness measures the hardness of materials like rubber and plastics, using Shore A (soft) or Shore D (hard) scales. It’s a standard for material selection and quality control.

What is Shore Hardness?

Shore Hardness is a measure of a material’s resistance to indentation, commonly used for rubber and plastics. It is determined using a durometer, which applies a specific force to the material. The Shore A scale is for softer materials, while Shore D is for harder ones. This method provides a standardized way to classify materials, ensuring consistency in quality and performance. The Shore hardness chart helps compare materials, making it easier to select the right one for specific applications. It is widely recognized and essential for industries relying on rubber and elastomers.

Shore A vs. Shore D Scales

Shore A is for softer materials, while Shore D measures harder ones. Both scales help classify rubber and plastics, ensuring precise material selection for industrial applications.

Differences Between Shore A and Shore D

The Shore A scale is designed for softer materials, such as flexible rubber, with a range of 0-100. Shore D, conversely, measures harder plastics and thermosets, ranging from 0-90. The primary distinction lies in their application: Shore A is ideal for elastomers requiring flexibility, while Shore D suits rigid polymers. Both scales use a durometer but differ in spring force and needle penetration depth. Understanding these differences is crucial for accurate material characterization in industrial manufacturing and quality control processes.

Measurement Process

The Shore hardness is measured using a durometer. Press the instrument’s needle against the material, holding it firmly for 15 seconds to ensure an accurate reading.

How to Measure Shore Hardness

To measure Shore hardness, use a durometer by pressing the needle firmly against the material’s surface. Ensure the material is at least 6mm thick and flat. Apply gentle pressure for 15 seconds to allow the needle to stabilize. The reading on the durometer indicates the hardness level, with higher numbers representing harder materials. For softer materials, use the Shore A scale, while harder materials require the Shore D scale. Refer to the Shore hardness chart to compare and interpret the results accurately.

Shore Hardness Chart

A Shore hardness chart provides a visual reference for comparing materials, showing Shore A and Shore D hardness levels. It helps determine material hardness and suitability for applications.

Understanding the Chart

The Shore hardness chart is a reference tool that correlates Shore A and Shore D hardness values, providing a clear comparison between different material hardness levels. It typically features two axes, with Shore A on one and Shore D on the other, allowing users to cross-reference values. The chart helps determine the suitability of materials for specific applications, ensuring compatibility and performance. By understanding the chart, manufacturers can select appropriate materials based on hardness requirements. It also aids in quality control, ensuring consistency in material properties across production batches.

Applications

Shore hardness is crucial for manufacturers in material selection, ensuring optimal production and product design for durability and performance in rubber and thermoplastic elastomers.

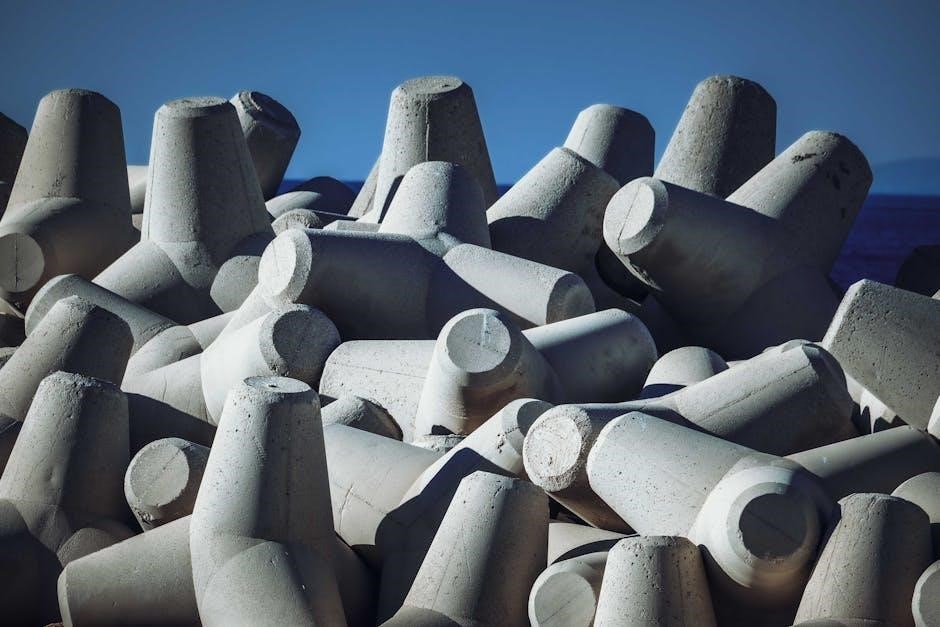

Industrial Applications

In manufacturing, Shore hardness is essential for selecting materials like rubber and thermoplastics. It ensures components meet performance and durability requirements in automotive, aerospace, and consumer goods. Proper hardness levels prevent material failure, reducing production costs; Manufacturers use Shore A for softer materials, such as seals and gaskets, while Shore D suits harder applications like industrial belts and tires. This standard ensures consistency in producing reliable products, making it a critical tool in quality control and material testing across various industries.

Comparison

Shore hardness is compared across materials using Shore A (soft) and Shore D (hard) scales, ensuring accurate material selection for specific industrial applications and performance needs.

Other Hardness Scales

While Shore hardness is widely used, other scales like Brinell, Rockwell, and Vickers are also employed for hardness testing. These methods are typically used for metals but can apply to plastics and composites. The Brinell scale uses a ball indenter, while Rockwell and Vickers utilize diamond indenters. Shore A and D scales remain the standard for rubber and elastomers, but understanding other hardness scales is useful for comparing materials across industries. Each scale has its specific application, and knowing their differences aids in selecting the right method for material evaluation and ensuring compatibility with international standards.

Factors Affecting Measurements

Temperature, material thickness, and testing conditions can influence Shore hardness readings. Ensuring accurate measurements requires controlling these variables and following standardized testing protocols carefully.

Variables to Consider

When measuring Shore hardness, several variables must be considered to ensure accurate results. Temperature plays a significant role, as higher temperatures can soften materials, leading to lower hardness readings. Material thickness is another critical factor; insufficient thickness may result in incorrect measurements. Additionally, the testing surface should be even and clean to avoid interference; The durometer’s calibration is also essential to maintain accuracy. Furthermore, the time of indentation should be standardized, typically around 15 seconds, to ensure consistency across measurements. By controlling these variables, reliable and reproducible Shore hardness values can be obtained, which are crucial for material selection and quality control in industrial applications.

Shore hardness is a vital parameter for evaluating rubber and plastics, ensuring material quality and performance. Referencing a Shore hardness chart PDF provides essential insights for precise material selection and applications.

Shore hardness is a standardized method to measure the hardness of rubber and plastics, ensuring material quality and performance. The Shore A and Shore D scales provide clear benchmarks for material selection, helping industries like manufacturing and engineering choose the right materials for specific applications. Understanding shore hardness is crucial for ensuring product reliability, safety, and durability. Referencing a shore hardness chart PDF allows professionals to make informed decisions, aligning material properties with application requirements. This measurement system plays a vital role in maintaining consistency and excellence in material science and engineering practices.

References

Key sources include ASTM D2240 standard, technical manuals, and industry publications. These provide detailed insights and methodologies for Shore hardness testing and material evaluation.

Further Reading

For deeper understanding, explore ASTM D2240 standard, technical manuals, and industry journals. These resources provide detailed methodologies, applications, and interpretations of Shore hardness testing. Additionally, publications focusing on material science and polymer engineering offer comprehensive insights into rubber and plastic properties. Online databases and manufacturer guides also serve as valuable references for practical applications and troubleshooting. These materials are essential for professionals seeking to enhance their knowledge and apply Shore hardness effectively in various industrial contexts.

PDF Chart

A PDF chart provides a convenient and printable reference for Shore hardness values, ideal for quick comparisons and practical applications in material selection and quality control.

Accessing the Chart

To access the rubber Shore hardness chart in PDF format, visit official materials testing websites or search for “Shore hardness chart PDF” online. Ensure the source is reliable for accurate information.

- Visit a reputable website or database.

- Search using specific keywords.

- Download the PDF for reference.

Always verify the chart’s authenticity and check for recent updates to ensure data accuracy and relevance.